A Manned Alternative

One possible compromise in the manned/automated tradeoff is to send the equipment on a low delta V flight and launch the human operators separately on a much shorter, high delta V flight. The astronauts would mine the body, start the materials on a slow trip back to cislunar space, and themselves make a fast trip back. It should be noted that any manned mission would have the possibility of refining some or all of the fuel required for the return trip.Teleoperated Missions

Teleoperation resolves some of the difficulties of automated operation. A greater range of the unforeseen problems the system will encounter become solvable. However, actions are carried out by the same actuation devices in both automation and teleoperation. This fact imposes limitations in mining operation control. The Viking lander case is illuminating. The Viking mission, which cost about $1 billion (in 1970 dollars, about $3 billion now), included an extendable scoop experiment that was teleoperated. Although the scoop was relatively simple in design and operation, with few degrees of freedom, first attempts to actuate it failed. A good deal of evaluation and effort ensued before the scoop was successfully operated.

Teleoperation from Earth would be somewhat hampered by a control delay due to the long distances and the speed of signal propagation. However, it seems likely that the effect could be overcome.

Mining in Zero Gravity

Although it might seem easier to move materials in zero gravity than on Earth, inertia, not overcoming gravity, is the major effect to consider. Little experience has been gained in weightlessness. One sample problem is that of holding fracturing and excavation tools to the face of an asteroid. On Earth, equipment hold-down is accomplished solely by gravity. Another sample problem is containing the excavated material, either large or small fragments. Rock fracturing places an initial velocity on the broken material. On Earth, gravity quickly collects the broken rock. In weightlessness, the broken rock will behave like out-of-control billiard balls, a potentially destructive game. Furthermore, the fines that are always generated by rock fracturing may obscure vision and clog equipment. Our study group did not have time to consider the full significance of working complex equipment in zero g, but we note that this problem needs in-depth study.

A Conceptual Asteroid Mining Method

The study group did not have the time or the resources to fully design a baseline asteroid mining method. This incomplete concept of an asteroid mining method is intended to illustrate how some of the problems could be overcome. As with the lunar proposal, the concept should be used to promote discussion of asteroid mining problems, but not to promote the method itself. Assuming that the delta V for the available asteroid is small and that only a modest amount of material is needed, I propose the following method to accomplish a first mission.

After arriving at the asteroid, the operators place one or more cables around the body. The asteroid proposed to the group for study was no more than a few hundred meters in diameter. Placing a cable around the body appeared to us much easier than anchoring the end of a shorter cable. Anchoring in rock can be a difficult process. If augering is used in weightlessness, a method must be devised to hold the augering tool down while it is working. The most desirable asteroids have very low strengths, good for mining but poor for anchoring. Quite long cables are possible, on the order of 1000 meters. The cable is easily placed and provides easy movement of the mining tool. One disadvantage of a long cable is the mass; for example, a cable 1 inch in diameter weighs 1.6 pounds per foot on Earth (has a mass of 2.4 kg/m).

The cable holds a cutter head or other rock-fracturing tool in place and provides sufficient working force for it. The cutter head is designed to excavate in addition to fracturing the soft rock. A cohical Kevlar collection bag is placed over the area to be mined and is held in place by the same cable (fig. 24). The flexible bag holds its shape because of the rotation of the asteroid. The spin also aids in collecting the fragmented asteroid material.

The cutter head travels back and forth along its restraining cable, cutting material until the collection bag is filled (fig. 25). The cutter is similar to the coal shear currently used in longwall operations but is designed to overcome the asteroid's low gravity and fling material past synchronous orbit so that centripetal force effects collection. Dust production around the cutter head remains a problem. Dusty environments obscure vision and thus increase problems in controlling teleoperated systems or in monitoring automated systems.

However, direct vision may not be so important on a body that proves to be homogeneous in structure and composition.

After the required amount of material is collected in the bag, it is "lowered" away from the body, allowing the bag and material to steal angular momentum from the asteroid. For low delta V return flights, there may be sufficient energy available to slingshot the load back to Earth. Deceleration at Earth could be accomplished by aerobraking. The collection bag might be designed to act as an aerobrake shield in addition to being reusable. The bag could also serve as a retort for carbonyl or other types of processing during return.

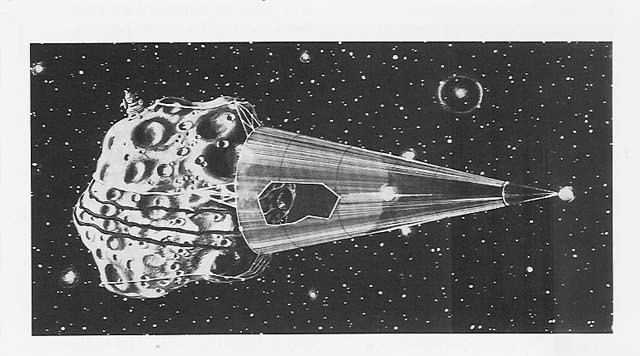

Figure 24

Concept for an Asteroid Miner

The shear breaks material and throws it away from the asteroid into the collection bag. The bag is moved when the shear moves to a new mining area. The collection bag can be used to transport the material to the Earth. The bag could also be used as an aerobrake shield or a processing container.

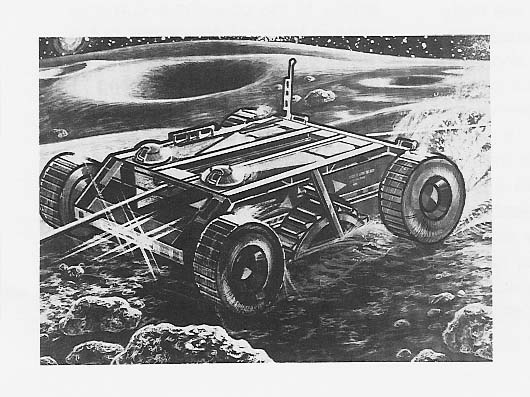

Figure 25

Detail of the Shear

The shear is derived from coal-cutting technology. It performs a dual role: it cuts the asteroid material and throws the material into the collection bag. In this illustration, the wheels are too small; larger, high-flotation wheels will help negotiate rough terrain. There should also be chutes to direct material past synchronous orbit and into the bag. And the shears conflict with the wheel path; they should be either inside or outside the wheels.

An alternative, but basically similar, method still uses the bag and cable. However, a large block of asteroid material is collected, not by mechanical excavation but by blasting material into the bag. Instead of a shear, which could have trouble negotiating the asteroid surface, an explosive is used. The cable holds in place a drilling machine, which drills a series of blast holes. Theprill holes and charges are carefully designed to excavate a large section of the asteroid. The explosive charges break out the desired amount of material, and the force of the explosion moves the material into the collection bag. Pattern drilling designed to create shaped explosions has achieved some success on the Earth and is finding more applications. The explosive method appears simpler in equipment and operation than the shear, but the blasting must have a very high degree of control. Uncontrolled fragmentation of the cabled body would be a disaster. I have not considered a suitable blasting agent. The reader can visualize this alternative method by imagining a drill rig instead of the shear in figures 24 and 25.

While the sizing of the return loads requires further study, the same basic mining scheme should be able to handle a range of sizes. It is not completely clear whether one large load or several smaller loads would be better, although several smaller loads might be more manageable, while allowing more flexible return flight plans.

Conclusions

Because it appears to be easier and cheaper to accomplish, the lunar mine is probably a better first project to exploit nonterrestrial materials than is the asteroid mine.

While not causing any increased transportation costs, the long, slow travel to and from the near-Earth asteroids would decrease the rate of return on capital investment.

As in the lunar LOX-to-LEO project, the asteroid mining system must be kept as simple as possible. Simplicity eases problems and lowers the costs of development, equipment, and operations.

A manned mission would make the mining operation much simpler, but it would greatly increase the complexity and cost of the deep space transport vehicle.

Teleoperation seems a good compromise between automation and manned missions, but the choice requires much more study.

Even if specific space program goals or higher costs eventually preclude an asteroid mission, the rich and varied asteroid materials require that the option of mining an asteroid be studied. Given a goal of providing a range of materials for use in cislunar space, lunar projects must be demonstrated to be superior before asteroid missions are abandoned.

References

Billingham, John; William Gilbreath; and Brian O'Leary, eds. 1979. Space Resources and Space Settlements. Specifically, David F. Bender, R. Scott Dunbar, and David J. Ross, Round-Trip Missions to Low-Delta-V Asteroids and Implications for Material Retrieval, 161-172; Brian O'Leary, Michael J. Gaffey, David J. Ross, and Robert Salkeld, Retrieval of Asteroidal Materials, 173-189; and Michael J. Gaffey, Eleanor F. Helin, and Brian O'Leary, An Assessment of Near-Earth Asteroid Resources, 191-204. NASA SP-428.

Johnson, Richard D., and Charles Holbrow, eds. 1977. Space Settlements: A Design Study. NASA SP-413.

O'Leary, Brian. 1983. Mining ttJe Earth-Approaching Asteroids for Their Precious

and Strategic Metals. In Advances in the Astronautical Sciences 53

(Proc. Princeton Conf. Space Manufacturing 1983, ed. James D. Burke and April

S. Whitt): 375-389. San Diego: American Astronautical Soc.

![[NASA]](images/NASAball.gif)

![[Ames Research Center]](images/arclogo1.gif)

|

WebWork: Al Globus, Bryan Yager, and Tugrul Sezen |

![[LifeSciences]](images/lslogot.gif)

![[Space Settlement]](images/splogosm.gif)

|