Requirements of the Lunar Mining System

The prototype lunar mining system should perform economically and dependably from startup to decommission. The system should meet the following requirements. However, some of these requirements may prove to be conflicting, in which case compromises and tradeoffs will have to be made.

Throughput Requirements

Because of the profit incentive, terrestrial surface mining techniques used in this country demand a significantly larger throughput than the 40 000 metric tons per year (or 10 metric tons per hour for a 4000-hour operating year) envisioned for the first lunar mine. Mining this quantity of material does not require advances in the state of the art of mining technology. Quite to the contrary, it requires scaling down the mining operation to maintain continuity in operations. For example, it may be advantageous to reduce the quantity of material excavated per unit load and increase the number of unit loads excavated per hour. The modest throughput requirements should result in increased flexibility in choosing the prototype lunar mining system.

Ruggedness of Equipment

The lunar mining equipment should be robust. It must withstand the rigors of normal mining operations, such as excavating and transporting abrasive dust, cobbles, and boulders; operating in a dusty environment; and operating continuously. In addition, it must operate in the hostile lunar environment with its severe temperature swings (except at polar sites).

Design Simplicity

The low throughput requirements encourage design simplicity, which will result in failure-resistant equipment. This design simplicity should extend to ease of repair, so as to minimize downtime. Thus, the prototype system should have few moving parts, be constrained in degrees of freedom, and be automated with exceeding care. To conserve energy, the mining and processing should take place as close together as possible.

Versatility

The unexpected is usually the most dependable occurrence in mining operations. Despite the care and thoroughness with which site characterization is performed, unexpected problems are inevitable once mining operations begin. For this reason the mining operation should be flexible and versatile enough to permit relatively easy relocation, reorientation, alteration in distribution network, and other changes during the operation cycle.

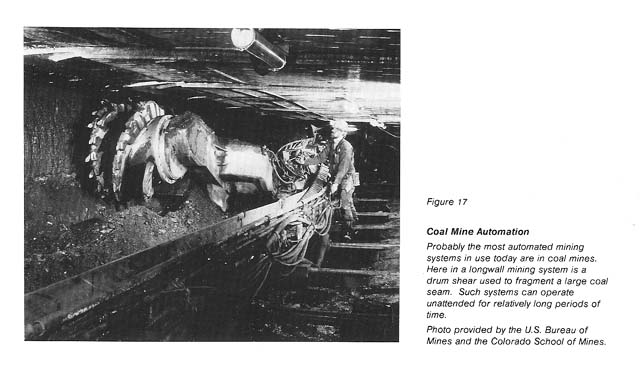

Automation

The mining system should be capable of automation to the level of sophistication of advanced automated systems at the time of implementation (see fig. 17). The system should also be flexible enough to incorporate the products of future robotics research. Full automation of routine mining operations should be incorporated within the prototype system.

The mining system should be instrumented and computer monitored to provide such operational information as power use, breakout force, and cable tension, so that stress and failure can be anticipated. In addition, mining systems having few degrees of freedom should be sought for early systems. Although laboratory automations have been demonstrated with numerous degrees of freedom and rudimentary tactile and visual sensors, it is not clear that these new advances will be sufficiently developed at the time of lunar resource exploitation.

![[NASA]](images/NASAball.gif)

![[Ames Research Center]](images/arclogo1.gif)

|

WebWork: Al Globus, Bryan Yager, and Tugrul Sezen |

![[LifeSciences]](images/lslogot.gif)

![[Space Settlement]](images/splogosm.gif)

|